PCCI provides design and engineering services in five key areas:

- Equipment Packaging for Rapid Response

- Heavy Lift Rigging and Transport

- Hyperbaric and Hypobaric Facilities

- Marine Salvage

- Ocean and Waterfront Facilities

Our licensed Professional Engineers, engineering technicians, construction managers, and quality assurance personnel combine their education and experience with the latest design software tools to provide the best mix of equipment and materials for the job.

Safety and environmental stewwardship remain paramount in all PCCI engineered solutions.

Equipment Packaging

PCCI’s expertise in the packaging of emergency response equipment and related cargos, and in the transport of bulk materials, includes:

- Bulk ISO hazardous substance shipping containers

- Packaging of emergency equipment for airlift and road transport

- Design and building of custom designed ISO containers containing:

- Emergency response command centers

- Fully equipped laboratories

- Machine and electronics shops

- Diving equipment and recompression chambers

- Chemical process filter systems

- Portable lighting systems

- Navigation and Communication Suites

- Reuseable containers for the storage, transport, and deployment of ship based systems

Heavy Lift rigging and Transport

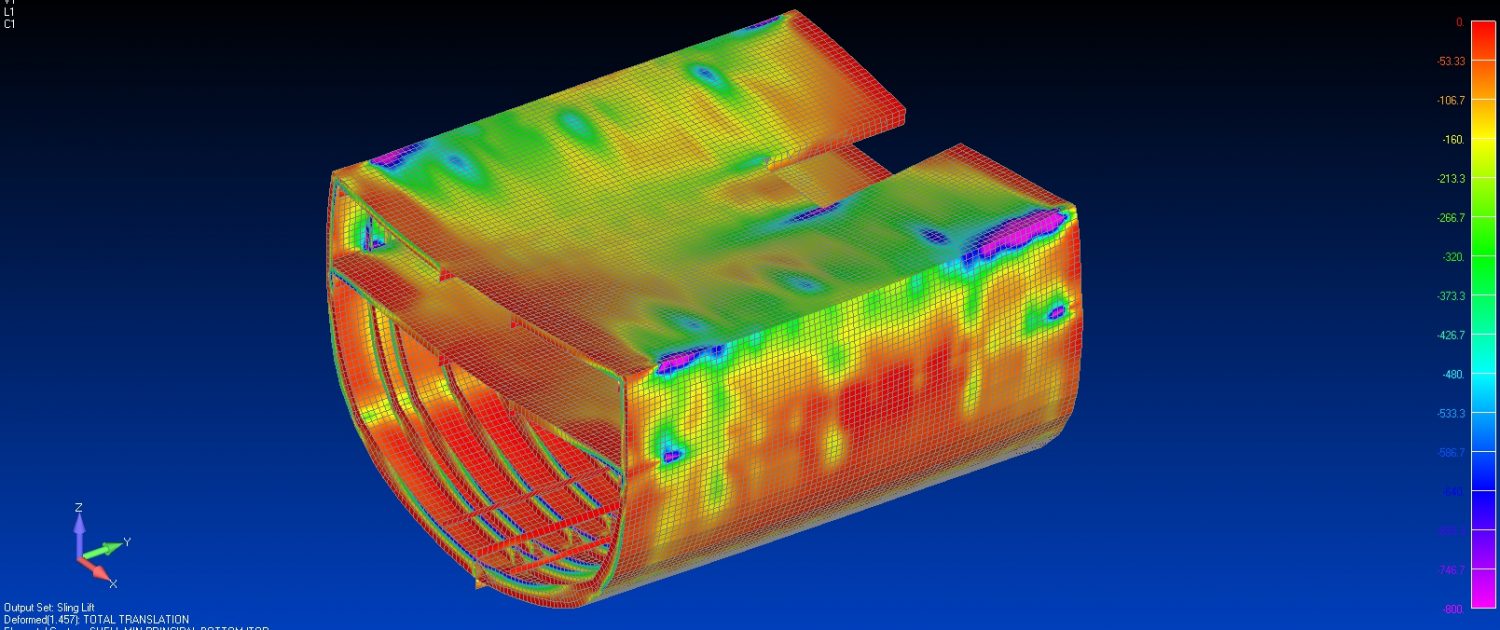

PCCI specializes in the engineering of equipment and systems for heavy lift marine cargoes. PCCI engineers and naval architects consider the structural and vessel stability aspects of each job in the design, detailed fabrication and installation of lift components.

Hyperbaric and Hypobaric Systems

PCCI has extensive design, engineering, and configuration management experience obtained in the acquisition, evaluation, maintenance, modification, prototyping, repair, and testing of hyperbaric components and systems including:

-

Medical Center hyperbaric facilities

-

Standard Navy double lock recompression chambers

- Transportable recompression chambers

- Emergency evacuation hyperbaric stretcher system

- Submarine rescue diving and recompression system

- Oxygen treatment pack units

- Fly-away mixed gas systems and chambers

- Diver life support equipment

- MK3 lightweight dive systems

Our Reimers Systems Division specializes in high quality hardware solutions for man-rated hyperbaric and hypobaric applications with special emphasis on medical hyperbaric applications.

Marine Salvage

PCCI uses both the General HydroStatics (GHS) and the HEC Salvage Engineering (HECSALV) computer program to provide estimates of the projected oil outflow, tidal and weather effects on the damaged vessel condition, and damaged hull girder strength and deflections.

PCCI offers:

24 Hour/7 Days a Week Salvage Engineering Program – PCCI has been retained by fleet owners and operators to provide salvage engineering assessments under emergency conditions 24 hours a day. This involves establishing electronic vessel files at PCCI where they are available to be exercised in emergency and training scenarios.

Salvage Equipment Procurement – Design drawings and operations manuals for fly away deep ocean lift systems, salvage pumping systems, and tow alarm systems

Site Safety Planning – Site Safety Plans for marine operations including at-sea exercises, pollution response and salvage operations.

Drills and Exercises – Simulated casualty HECSALV analysis to facilitate realistic salvage response training for spill managers.

Weapons Effect Test Engineering Support – Stability calculations and predictions, ballasting plans, on-site engineering, and post-test analyses.

Towing Analyses – Analysis for tow planning, pre-towing inspection of rigging.

Ocean and Waterfront Facilities

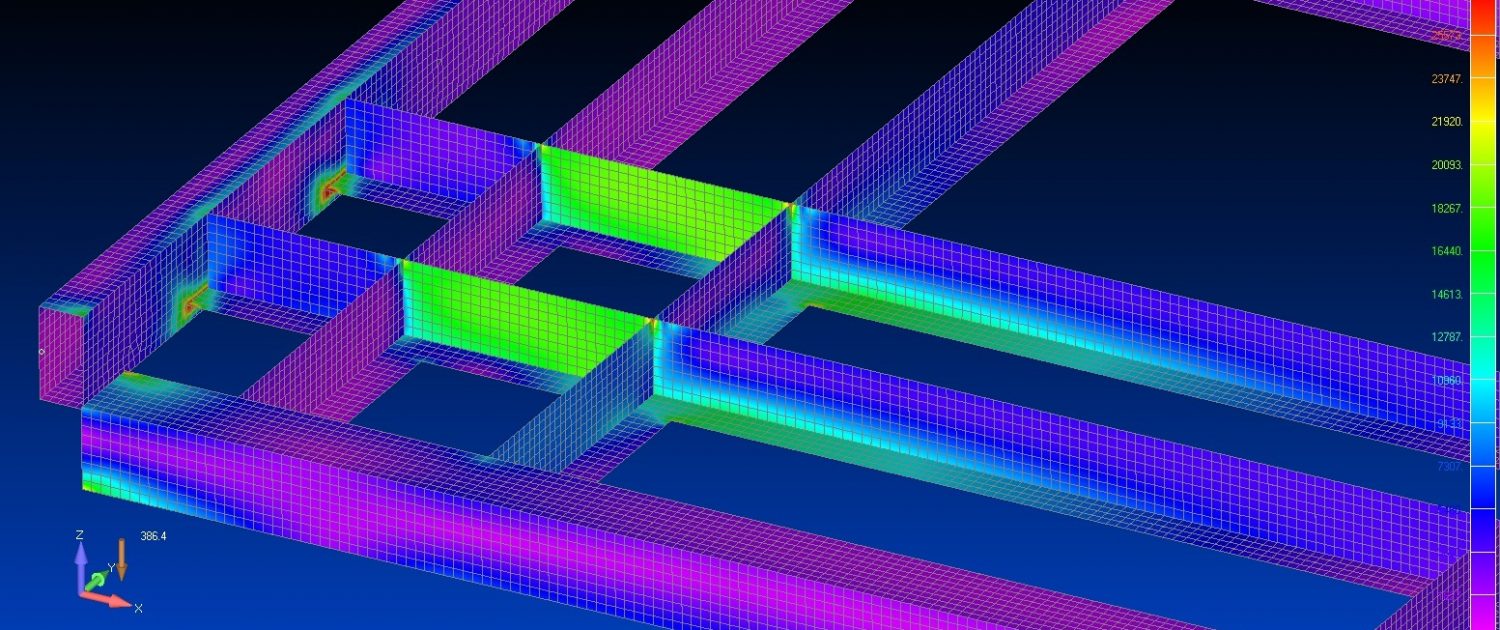

PCCI provides professional engineering services across multiple disciplines to offer an array of ocean and waterfront engineering services. Design capability includes computer-assisted hydrodynamic and structural modeling and analysis, drawings, engineering and cost tradeoff studies, test planning, procurement specification development, and acceptance testing. We have provided analysis, design, modification, fabrication and test of systems including:

- Cofferdams

- Drydocks

- Floating Barriers

- Fuel Terminals

- Marine Railways

- Moored Buoys and Ships

- Renewable Energy Platforms

- Submarine Cables

- Towed Systems

- Underwater Ranges

- Wharf, Pier and Piling repairs

Field Experience

PCCI engineers benefit from real world experience gained while on the job site overseeing the installation of equipment and systems they have designed.

Their hands-on experience in the field with marine facility installations, ship salvage, oil spill response operations, and underwater ship repairs translates back to the office and allows us to design and engineer systems to overcome the difficult environmental and working conditions in which they must operate.

PCCI’s Alexandria, VA headquarters has 6,600 square feet of offices, meeting rooms, library space, computer aided drafting equipment, networked computers, reproduction facilities and graphics equipment. PCCI utilizes ANSYS, Rhino 3D, AutoCAD, Solid Edge, ESRI ArcGIS, Global Mapper, and MS Office 365, as well as specialized software for ship handling and mooring design analysis including GHS, HECSALV, OPTIMOOR and ORCAFLEX.